A slate DPC is a type of moisture barrier that is made of slate and is used to prevent the passage of water through walls and foundations. The slate DPC is typically installed in the mortar joint between the brickwork or stonework of a building, creating a barrier that prevents water from penetrating into the walls and floors. Slate is a durable and long-lasting material that is resistant to water, making it an effective choice for a damp proof course. Additionally, slate is a natural material that blends in well with the aesthetic of traditional buildings, making it a suitable choice for historic or listed buildings. However, slate DPC is relatively expensive and can be difficult to install, especially in existing buildings. It is important to consult with a professional builder or engineer before installing a slate DPC to ensure that it is the best choice for your specific situation.

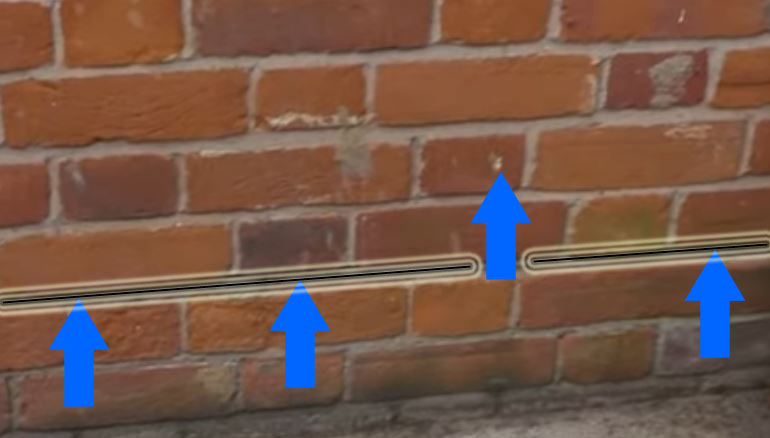

A plastic DPC is a type of moisture barrier that is made of plastic and is used to prevent the passage of water through walls and foundations. The plastic DPC is typically installed in the mortar joint between the brickwork or stonework of a building, creating a barrier that prevents water from penetrating into the walls and floors.Plastic DPCs are widely used in construction because they are relatively inexpensive, easy to install, and effective at preventing moisture penetration. They come in various forms such as sheet, liquid and some are even self-adhesive. Plastic DPCs are made of a variety of materials such as polyethylene and polypropylene, which are resistant to water and rot. They are also flexible, allowing them to conform to the contours of the walls and floors of a building. Additionally, they come in different thicknesses and widths to fit most building requirements. It is important to note that plastic DPCs should be installed correctly and be of the correct specification for the building, to ensure that they are effective in preventing moisture penetration. It is always recommended to consult with professional builders or engineers before making any decisions about moisture barriers in construction.

A heat applied bitumen DPC is a type of moisture barrier that is made of bitumen and is used to prevent the passage of water through walls and foundations. The bitumen DPC is typically installed by heating the material and applying it in a liquid state to the surface of the wall or foundation. As it cools, it solidifies and forms a barrier that prevents water from penetrating into the walls and floors. Heat applied bitumen DPCs were widely used in construction for many years because they were durable and long-lasting. However, these days it’s often considered a historic or archaic method and not viewed favourably buy building surveyors. Despite general feelings of disapproval by developers, builders and surveyors, heat applied bitumen DPC has good resistance to both water and chemicals. The installation process for heat applied bitumen DPCs typically involves heating the material to a liquid state using a heater or torch, and then applying it to the surface of the wall or foundation using a brush or roller. The material then cools and solidifies, forming a barrier against moisture penetration. It is important to note that the installation of hot applied bitumen DPCs should be done by trained professionals and following the manufacturer’s instructions. It is also important to ensure that the surface is clean, dry, and free of any contaminants before application to ensure proper adhesion and effectiveness of the material.

A bitumen felt DPC is a type of moisture barrier that is made of bitumen-saturated felt and is used to prevent the passage of water through walls and foundations. The bitumen felt DPC is typically installed in the mortar joint between the brickwork or stonework of a building, creating a barrier that prevents water from penetrating into the walls and floors. Bitumen felt DPCs have been used in construction for many years, and are relatively inexpensive and easy to install. They are made by saturating a felt material with bitumen and then rolling or folding it to the desired width. The felt is then inserted into the mortar joint between the brickwork or stonework of a building. However, old bitumen felt DPCs can be less effective than other types of DPCs and may have a shorter lifespan. They can be subject to deterioration over time due to exposure to water and UV light. They can also be difficult to remove and replace, making it difficult to carry out repairs or maintenance. It is important to note that if you have an old bitumen felt DPC and suspect that it may not be performing effectively, it is best to consult with a professional builder or engineer to determine if it needs to be replaced. Newer and more effective DPCs materials and methods are available today.

An electro-osmosis DPC (EODPC) is a type of damp proofing system that uses an electrical current to reduce the amount of water that can penetrate the walls of a building. The system consists of a layer of material, such as a polymer, that is installed on the exterior of the wall and a series of electrodes that are placed within the wall. When the electrical current is applied, it causes the water in the soil to be drawn away from the wall, effectively creating a barrier that prevents water from entering the building. EODPC is used as a method of damp proofing in new construction and as a remedial solution in existing buildings.

A ceramic cylinder DPC is a type of damp proofing system that uses ceramic cylinders to create a barrier against water penetrating the walls of a building. The ceramic cylinders are typically made from fired clay or a similar material and are installed in a horizontal layer within the walls of the building, typically in the bed joint of the masonry. They are about the size of a small tube of lip balm. The ceramic material is highly porous and allows water vapor to pass through it, but it is not permeable to liquid water. This means that the ceramic cylinders can prevent water from entering the building while still allowing any trapped moisture to evaporate, thus preventing the build-up of mold and mildew. This method is considered as a reliable and effective method of damp proofing, it’s often used as a remedial solution in existing buildings with damp problems.

CHEMICAL INJECTION DPC

Chemical injection DPC is a method of damp proofing that involves injecting a chemical solution into the walls of a building to create a barrier against water penetration. The chemical solution is typically a silicone-based or solvent-based material that is injected into the masonry using specialized equipment. Once the chemical solution has been injected, it expands and hardens to form a waterproof barrier within the wall. Chemical injection damp proof course is commonly used as a remedial solution in existing buildings where there is evidence of rising damp. It’s a cost-effective solution and can be done quickly. However, the chemical solution used for injection can be toxic, and the work should be done by professional and trained person. The effectiveness of this method depends on the quality of the chemical used, the skill of the applicator, and the condition of the wall into which the chemical is injected.